E-mail:1527378483@qq.com

E-mail:1527378483@qq.com

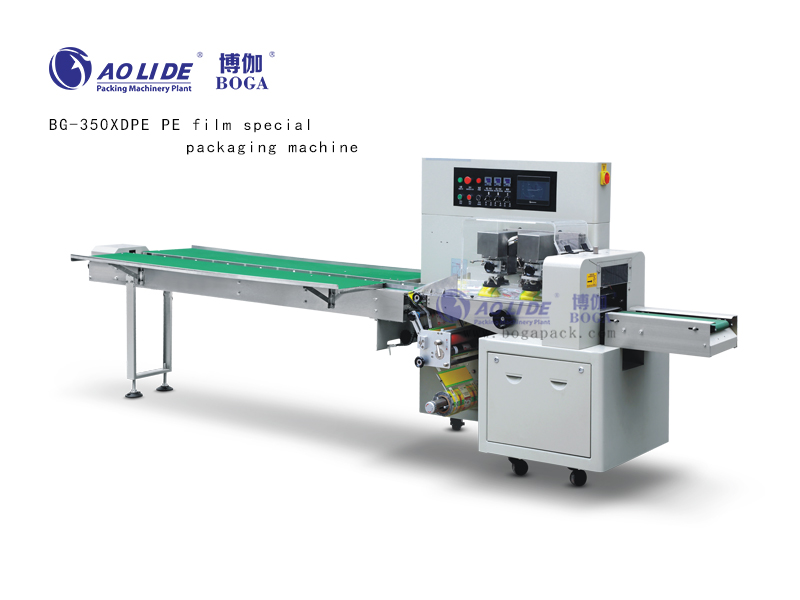

Main performance and structural characteristics

1. Three servo motors and PLC control, the bag length is already cut, without the need to adjust the air travel, one-step positioning, time-saving and film saving

2. Equipped with anti aircraft bag function, with automatic material packaging and no material waiting status.

3. Fault self-diagnosis function, clear fault display at a glance.

4. High sensitivity photoelectric eye color tracking, digital input of sealing position, making the sealing position more accurate.

5. Temperature independent PID control, better suited for various packaging materials.

6. Positioning and shutdown function, without sticking the knife and wasting the envelope.

7. The transmission system is simple, works more reliably, and maintenance is more convenient.

8. All controls are implemented by software, making it easy to adjust functions and upgrade technology, never falling behind.

Technical specifications

Model BG-350XDAN

Film width Max.340mm

Bag making length 150-6000mm

Bag making width 50-150mm

Mold roll diameter Max.320mm

Roll film material and thickness OPP composite film 0.03-0.06mm

Product height Max.60mm

Control mode PLC+Chinese and English operation interface

Speed 10-25 meters/minute (depending on actual situation)

Power 2.8KW

Voltage AC 220V 50Hz 2-phase power

Weight 450KG

Size L3600 * W810 * H1124mm

Electrical configuration

Serial Number Name Brand Quantity

1 PLC Xinjie 1

2 Touch screen Xinjie 1

3 Temperature control meter Yatai 1

4 Electric Eye Yatai 2

5 Encoder Changchun Rongde 1

6 Combination switch GLELE 3

7 Air switch Tianzheng 1

8 Servo motor Xinjie 3

9 Proximity switch Omron 1

10 switch power supply Mingwei 1

11 Solid State Relay Schneider 3

12 Intermediate relay Omron 1

Applicable scope

It is suitable for packaging various regular objects such as food biscuits, rice noodles, snow cakes, egg yolk pies, chocolate, bread, instant noodles, moon cakes, daily necessities, hardware tools and industrial parts, vegetable and fruit cartons or trays.

Optional device: optional according to different customer needs

1. Date coding machine 2, punching machine 3, all stainless steel frame 4, labeling machine 5, inflation device 6, exhaust device 7, no material shutdown function 8, butterfly hanging hole/circular hanging hole