The following 6 items introduce how customers choose pillow packaging machines

1. Packaging speed is an important factor that customers need to consider when choosing a machine. When the customer determines the expected output, it also determines the speed of the pillow packaging machine. Customers are mainly based on production capacity. The packaging method of the current packaging machines on the market determines the packaging speed. For example, the packaging speed of the reciprocating packaging machine is relatively slow, and the rotary packaging machine is relatively fast. The packaging speed is also different according to the size of the product

2. This is determined by the customer's future planning and product diversity development, such as ordinary motors, variable frequency electric power machines, but the future development is unmanned and automated factories, so you need to purchase at the beginning Choose some mid-end equipment as much as possible, so that it will be easier and more reliable for the later stage of the machine to become a production line or upgrade of the machine.

3. Operation and safety

The packaging machine also needs adjustment and installation by the operator, including some necessary settings and adjustments to the machine when packaging different materials. The easier and simpler these tasks are, the better, which not only saves time, but also does not require special training for operators, which can save money. A lot of manpower and material resources,

4. Environmental adaptability

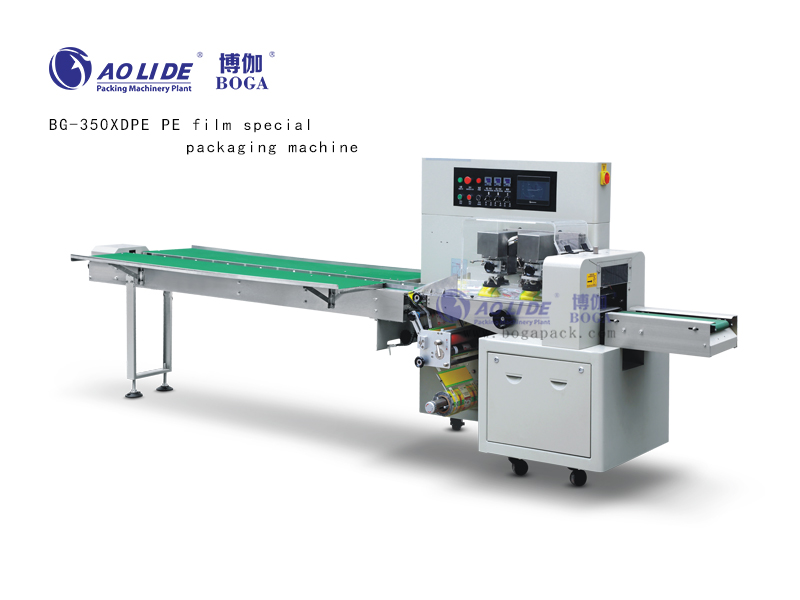

Due to the different packaging materials, the operating environment of the machine is also different. When selecting the equipment, the production environment should be taken into account in the purchased technical parameters to prevent the machine from failing to meet the packaging requirements required by the customer. Pillow packaging machine.jpg

5. Try to choose some strong and reliable companies from large manufacturers. Companies that have a long time in the industry have more experience and better after-sales service technology or product quality in the future. Customers and door-to-door inspections of the manufacturer's actual situation.

6. The rationality of the design and the convenience of operation are also an important factor in the selection.

- Daily maintenance and cleaning of pillow-type food packaging machine

- How much is a pillow-type mask packaging machine

- KN95 mask automatic packaging machine

- Hardware packaging machinery application range

- How to choose the right pillow packaging machine for you?

- What are the differences between common pillow packaging machines?

- Seven suggestions on how to buy a frozen food pillow packaging machine

- Daily maintenance and cleaning of pillow type food packaging machine

- Prev:What are the differences between common pillow packaging machines?

- Next:Hardware packaging machinery application range